Granulation, Granulators

The correct term is ‘agglomeration’ or ‘agglomerate granulation’. The term granulation can also describe a comminution process, e.g. when a solid is comminuted into a collection of particles / granules. Please read our detailed glossary article ‘Agglomerating’ and our blog post on ‘Agglomerating’.

Powder mixers can agglomerate during mixing. Agglomeration processes can be carried out either continuously or discontinuously.

The continuous mode of operation is often preferred when bulk materials are to be agglomerated.

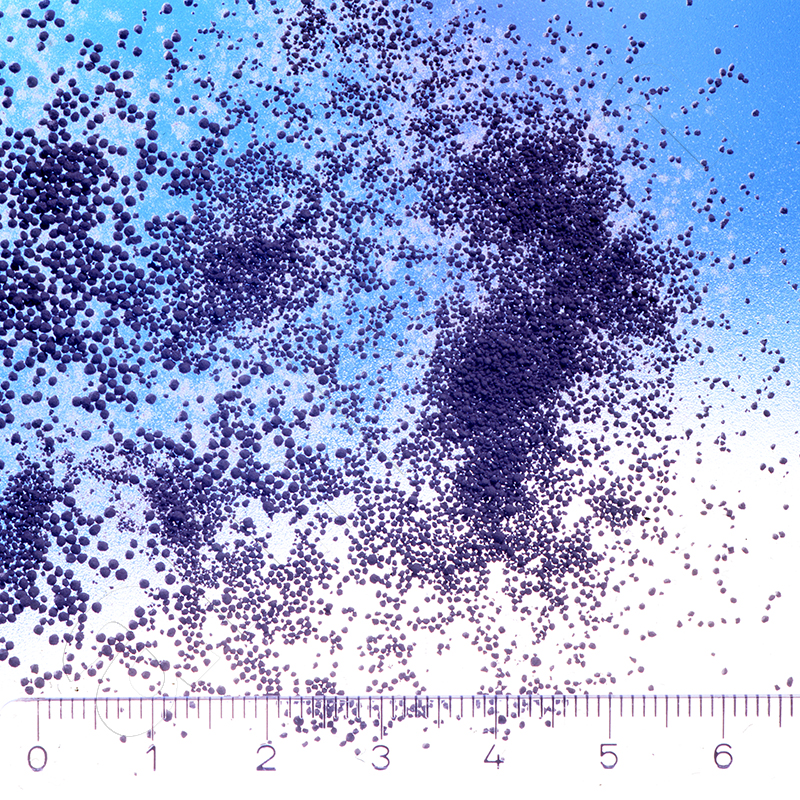

Typical applications for an annular gap mixing granulator RMG are Tablet masses, instant tea, baking agents, sugar substitutes, food colours, cellulose derivatives, building and insulating materials, hot-melt adhesives, carbon black and colour pigments, starch, detergents, pesticides, other powdered chemicals, toners, colour pigments, ceramic colours, sintered materials, foundry covering compounds, metal powders ....

Please read our detailed glossary article ‘Agglomerating’ and our blog post on the subject of ‘Agglomerating’.