Instant beverage powder homogeneously mixed

Instant drink powders can be stored well when dry, but dissolve or swell quickly when they come into contact with a suitable liquid. Ideally, the resulting soft drink is immediately homogeneously mixed and ready to drink.

Effervescent drinks in sachets, effervescent tablets in tubes, medicines in granules that dissolve directly on the tongue, iced tea powder in wide-mouth jars, cappuccino in sachets, cold-brew tea bags or energy drinks for sports - even if we are often not aware of it: We encounter instant drinks in a wide variety of forms every day. The powder is stirred into the drinking water and a drink is ready to drink, whether at home, in space, in a submarine or when traveling.

Instant drinks are in demand worldwide. Although instant powder looks like an ordinary, sweet mass product at first glance, its production is not trivial. Important properties must be fulfilled:

- Fast resolution,

- Bioavailability

- Mouthfeel and

- Combining taste and enjoyment.

Ideal homogeneity with minimal energy input

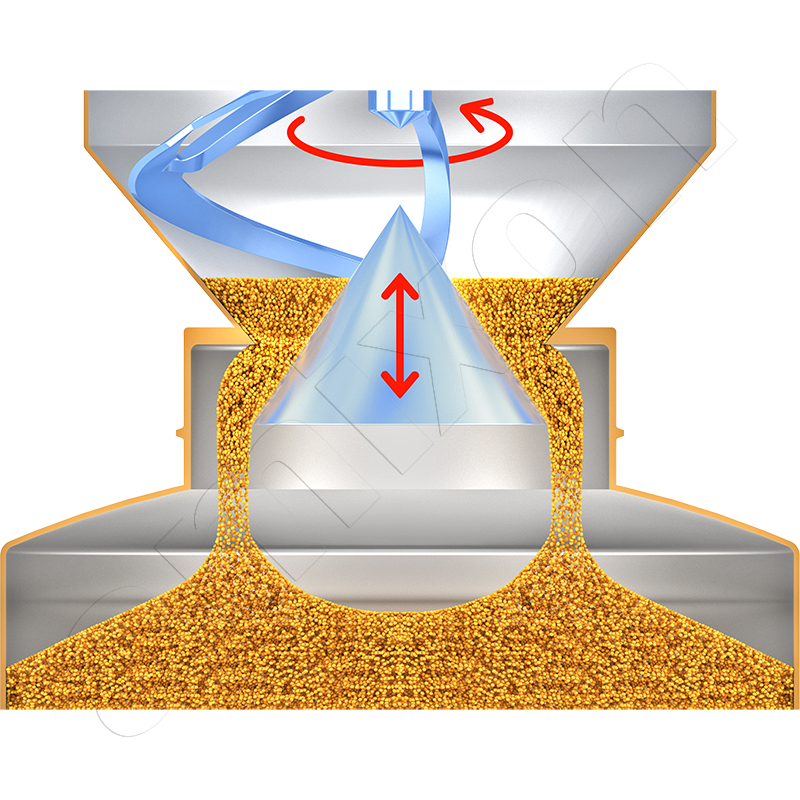

Thanks to the SinConvex® / SinConcave® mixing tool, amixon® conical mixers achieve ideal mixing qualities that can no longer be improved in practice.

Standard bulk containers are used for loading and emptying. This means that the weighing, feeding, mixing and filling operations are decoupled. The system has a particularly ergonomic design and meets the highest hygiene requirements. It is also used for medicinal premixes, for example. Cleaning can be carried out dry or wet. Free-flowing products are emptied completely.

All sensitive areas are visible through large inspection doors!

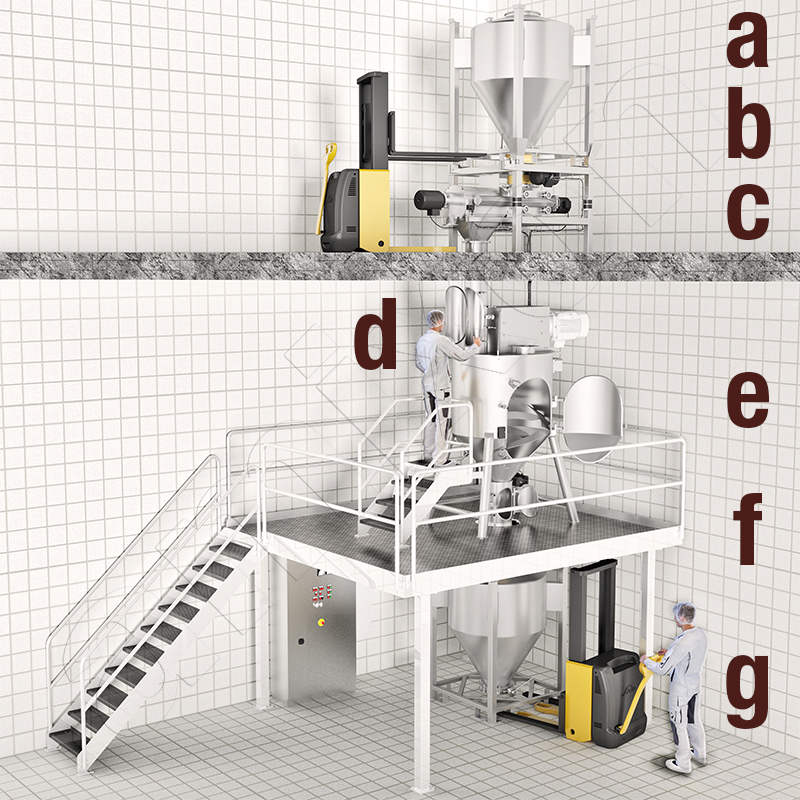

a. Standard container for 1500 liters with dust filter

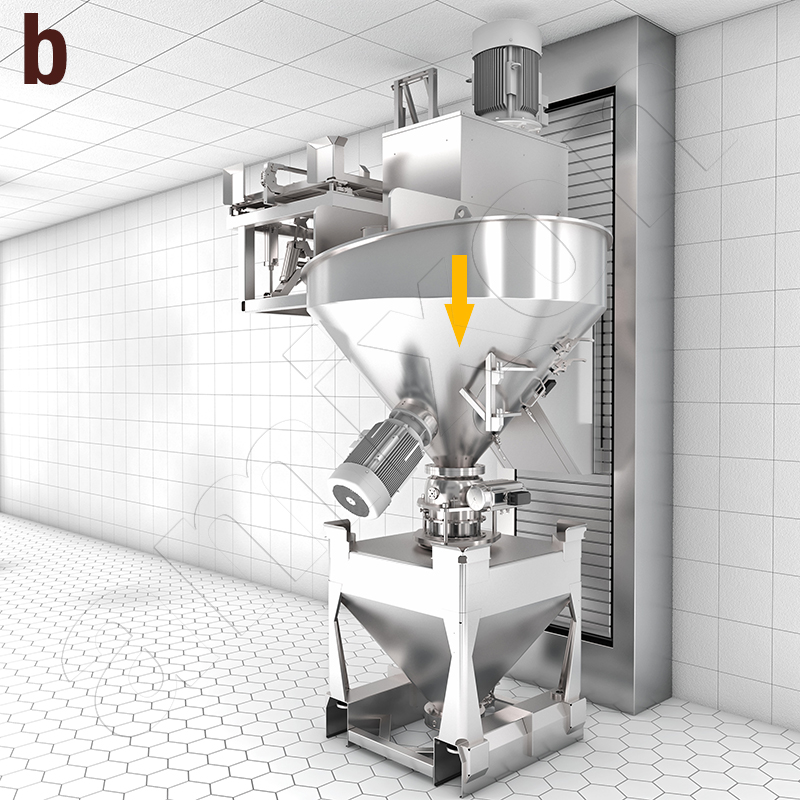

b. Docking system for containers (dust-tight) with vibrating device

c. Eddy current screening machine (quick to dismantle, easy to clean)

d. Inlet connection to the amixon® mixer with dead space-free inspection flap - safety-locked

e. amixon® conical mixer with large inspection door

f. Outlet nozzle with large inspection flap

g. Alternatively: the same bulk goods container for the mixed goods

This mixing system is particularly hygienic. It can be used universally for all types of instant beverage powders and ice cream powders. Premixes for baby food and diet food are also produced in this way. Ingredients include trace elements and micro-components such as iron, vitamin C, calcium, zinc, iodine, copper, selenium, chromium, fluorine, potassium, sodium, magnesium, phosphorus, vitamins, vitamin B2, probiotics, prebiotics, omega-3 fatty acids, omega-6 fatty acids, .....

Preservation through dehydration

Preservation by dehydration. In 1925, the founders of Robert Frigeo GmbH developed Ahoj-Brause as an inexpensive lemonade powder. Despite the fact that Ahoj effervescent powder was even drunk with melted snow on Himalayan expeditions, it was not considered a typical beverage powder by consumers for a long time. Rather, it has remained a sweet and sour sweet for children to this day. You enjoy the powder in your mouth without adding water. "Sodium hydrogen carbonate reacts with citric acid, tartaric acid, malic acid".

In 1937, Max Morgenthaler, a food technician at Nestlé, developed instant coffee for a completely different reason. The availability of coffee beans was very variable. Sometimes more coffee beans were harvested than could be marketed and the coffee threatened to spoil. At other times, crop yields were lower than demand. Spray-dried or as freeze-dried granules, the coffee could be stored for a long time. And a new clientele was tapped into, who particularly appreciated the quick preparation of coffee.

The range of instant drinks on offer is vast and constantly growing

The success story of instant drinks continues to this day: Twenty years after the invention of instant coffee, food technologist William Mitchell developed the beverage powder Tang for the General Foods company. By mixing the instant powder with cool drinking water, an excellent refreshing drink with different fruit flavors was created. Manned space travel also took advantage of this success. Seaweed has been enriched with high-quality vitamins, nature-identical active ingredients and trace elements. This further development supplied the Apollo crew on their journey to the moon and back in 1969. Instant beverages are indispensable for military operations and for supplying food in crisis areas. Increased sugar content and starch derivatives can compensate for short-term energy deficits in the body.

Experts know that the bioavailability of the ingredients is only maintained if the mixing process is low-shear. Amorphous particle structures from spray granulation must not recrystallize due to pressure and friction. Any shear stress during mixing must be avoided.

Process optimization: The end product should have ideal instant properties, whether fruit tea, iced tea, cappuccino powder, ice cream powder, clear broth or other hot and cold drinks. The particle structures should be retained and homogenization should be "minimally invasive". But the path from a new product idea to an automatically operating production plant can be a long one. amixon® will be happy to accompany you and ensure your "agglomerative mixing" value-added step. We prove this hundreds of times over with references and mixing tests in the amixon® technical center. There you can see the processes, the available equipment and the amixon® quality standards. Conversely, the amixon® team gets to know your requirements. Your requirements are our top priority.

Instant coffee and cappuccino

Today there are all kinds of instant coffee drinks. Many hot drinks can even be prepared in vending machines.

The example of a cappuccino mix drink illustrates the complexity of production: Sugar is finely ground and agglomerated in a fluidized bed. Cream powder and milk powder are obtained by spray drying and agglomerated. Instant coffee is produced by spray-drying or freeze-drying. Flavors and lecithins are available in powder form. All these sensitive components are mixed and the requirement is: The existing agglomerations must not be destroyed. No dust must be produced. The mixing quality must be exact.

amixon® solves these mixing tasks excellently and offers three mixing systems for this purpose. All amixon® mixers guarantee an extremely gentle mixing process:

- KoneSlid mixer "KS" for batches up to 2.5 m³.

- High-performance twin-shaft mixer "HM" up to 12 m³.

- Cone mixer "AMK for continuous mixing processes.

The mixing processes can even be optimized, for example, if a special foam formation is required.

End of the Line Mixing

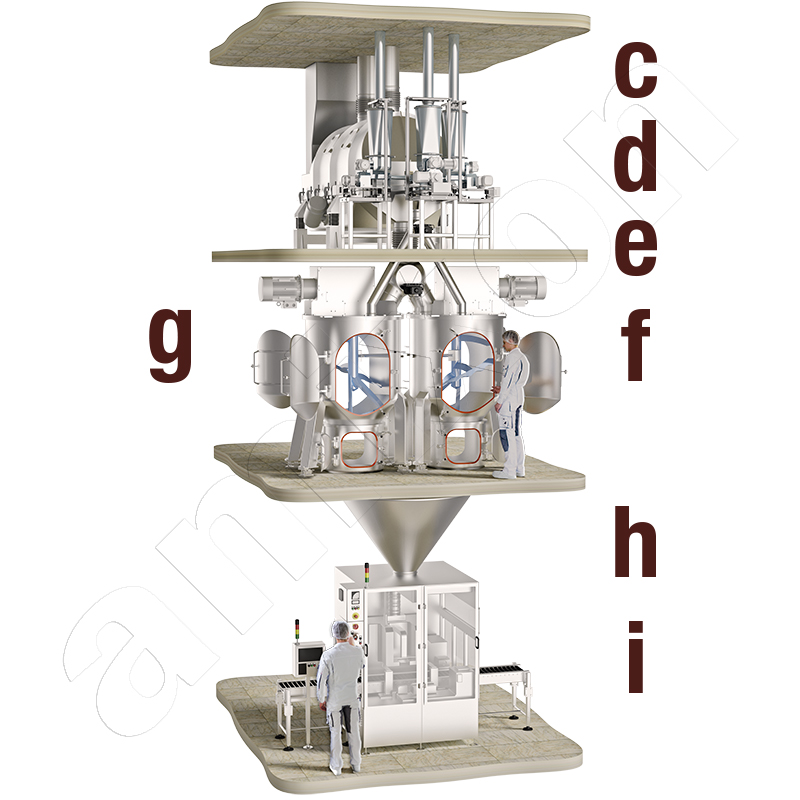

The spray tower continuously produces dry powder. This is agglomerated and cooled in the fluidized bed. Other nutrient supplements are weighed in at the same level. Two KoneSlid® mixers mix alternately in batches. Optimum mixing quality is achieved after 20 to 60 seconds of mixing time! Complete emptying also only takes a few seconds! The filling machine works continuously.

c. Fluidized bed agglomerator/cooler with control screen

d. several gravimetric feeders for powdered nutrient additives

e. Pipe switch

f. KoneSlid® mixer 1 on load cells

g. KoneSlid® mixer 2 on load cells

h. Collecting funnel

i. Filling machine for end consumers; packaging: Bags, cans, folding boxes

With these two KoneSlid® mixers from amixon®, the spray-dried product is enriched with heat-sensitive additives such as bacterial cultures and trace elements.

Double-shaft mixer HM for large batches up to 12 m³

Instant beverage powders consist of agglomerated individual components, some of which are in encapsulated form. They are also sensitive to abrasion. The dust produced by the friction and rounding of the mixed particles not only changes the taste. The fines collect at the bottom of the packaging and give the impression of a low-quality residue. In addition, the dust tends to float on the liquid and makes it difficult for it to sink. In the worst case, the dust fraction is trapped by the liquid. Lumps form which are difficult to dissolve. The problem can only be solved if the mixer quickly achieves ideal mixing qualities. Short mixing times and slowly rotating mixing tools mean minimal energy input.

Country-specific taste preferences determine the recipe ingredients

The powder formulation defines other product-specific properties such as cloudiness, texture, viscosity, mouthfeel and coloration. The country-specific taste preferences are interesting. While pineapple and orange are among the favorite flavors in South America, mango ranks far ahead of orange in the Arab-Persian region. Whereas in many Asian countries, lychees are preferred in cold drinks.

With a water activity of well below 4%, microbiological stability is guaranteed in the long term. Assuming clean production conditions and suitable packaging, the instant beverage powder remains free from mold toxins even without refrigeration. Liquid high concentrates can hardly offer this level of safety.

Economic and ecological aspects

Only 20 g of drink powder is needed to prepare a 200 g portion of drink. Instant beverage powders are space-saving compresses that generally do not require refrigeration. They are easy to transport - through the most diverse climate zones. Care must be taken to ensure suitable packaging.

The undesirable oxidation of the instant beverage powder can be counteracted by inertization: Mixers from amixon® are not only permanently gas-tight. They are also pressure/vacuum-tight on request. This allows a vacuum of minus 950 mbar to be applied during mixing to remove the ambient air (oxygen) from the powder. Atmospheric pressure is then restored in the mixer by introducing a nitrogen-carbon dioxide mixture.

Complete emptying; self-cleaning

Let's allow ourselves the utopia of having a mixing system that empties itself 100%. Any cleaning would then be superfluous. 100% raw materials become 100% products. No residues, no cleaning, contamination-free production.

Unfortunately, this does not yet exist in practice, but there are iterative developments in this direction. The KoneSlid® mixer is capable of emptying free-flowing mixes almost one hundred percent - in just a few seconds.

The practical methods of mixer cleaning are

- Intelligent control of mixing jobs, in which any residues are removed with the aid of rinsing batches.

- Manual dry cleaning using a vacuum cleaner

- Manual or automatic wet cleaning

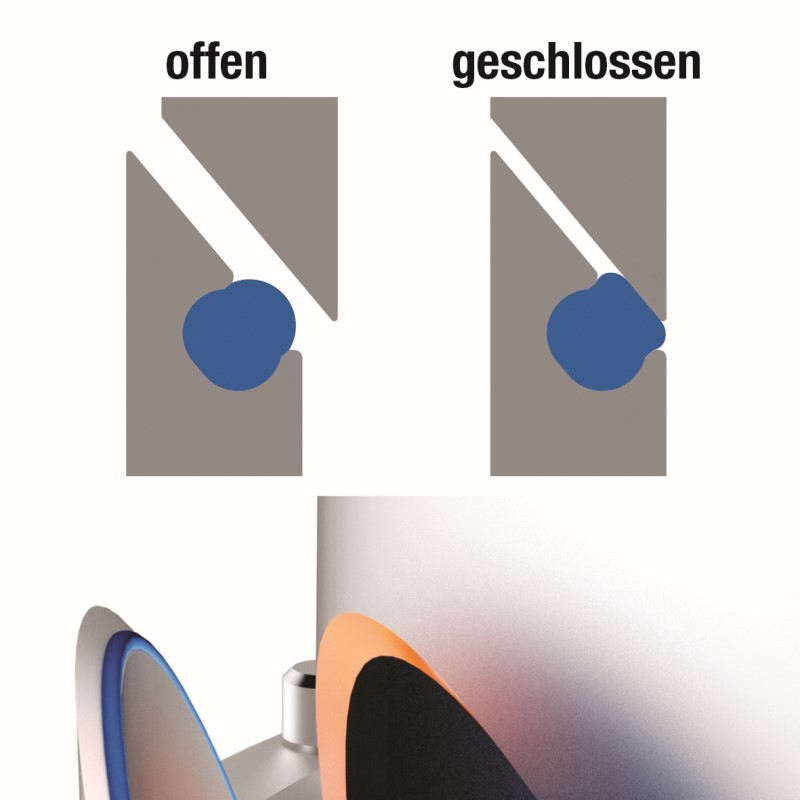

In any case, it is helpful if the mixer has large inspection flaps. Ideally with the dead space-free OmgaSeal®.

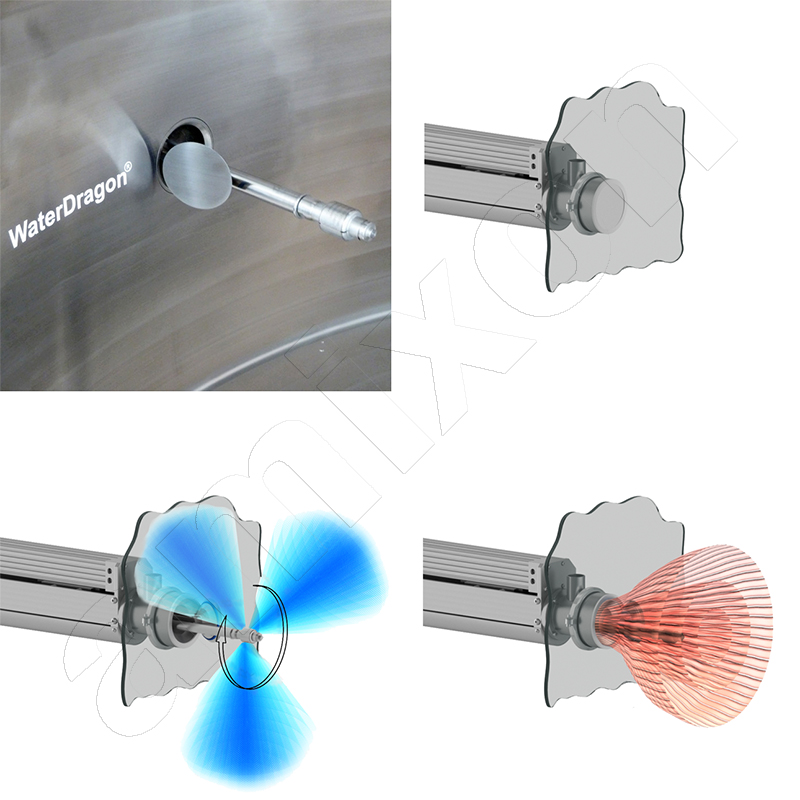

WaterDragon® automatic washing and drying

You see WaterDragon® open, the washing nozzle is extended. The wash nozzle rotates slowly and jets the wash water forward, to the side and to the rear without leaving any dead space. After wet cleaning, warm air flows through the large opening into the mixing chamber. Drying is extremely fast and thorough. After drying, the washing nozzle retracts from the mixing chamber. WaterDragon® closes without leaving any dead space. The mixer rotates slowly during wet cleaning and drying.

Visit amixon GmbH in Paderborn

During a tour of our workshops, you will learn how amixon® is customized to customer requirements. You are also welcome to bring your mixed goods with you. Mixing tests in our technical center will convince you. Mixing tests in our technical center provide a wealth of knowledge.

© Copyright by amixon GmbH